PET Flakes Recycling & Pelletizing Line

PET bottle flakes was forbidden import to China from June, 2017, so we spent more than 3 months to test special extruder for PET flakes. Finally we found a good solution which can keep good IV and color for PET flakes recycling.

- IV can be kept over 95%, 0.63-0.7

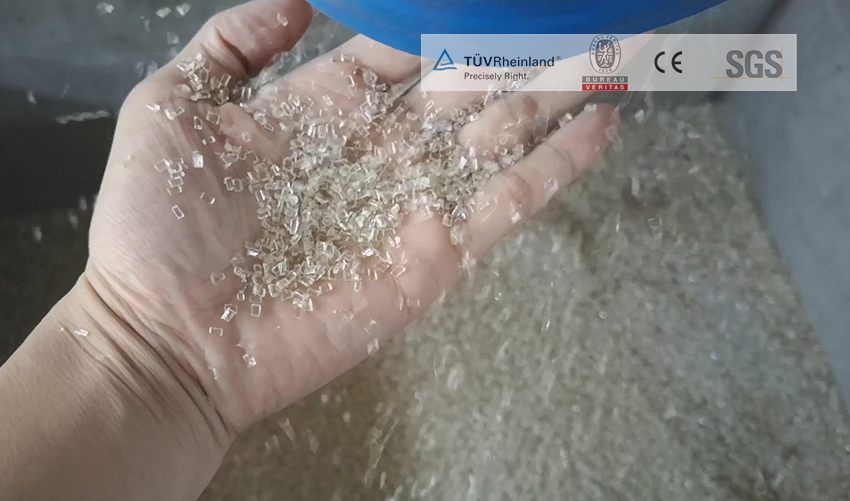

- Pellet Transparent and Beautiful

- Two solutions for your flakes

- Save more energy

- Save more budget for you

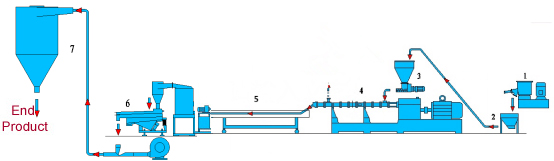

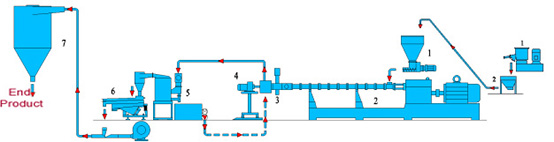

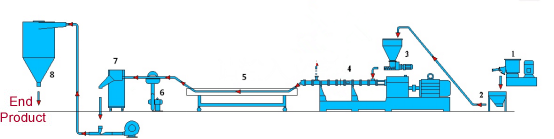

Twin Screw Extruder For PET Flakes Pelletizing Line

PET bottle flakes was forbidden import to China from June, 2017, so we spent more than 3 months to test special extruder for PET flakes. Finally we found a good solution which can keep good IV and color for PET flakes recycling.

- IV can be kept over 95%, 0.63-0.7

- Pellet Transparent and Beautiful

- Two solutions for your flakes

- Save more energy

- Save more budget for you

Advantages of Our PET Flakes Pelletizing Line Twin Screw Extruder

- Good Dispersion and Compounding

- Easy Solution For Cleaning the Screw

- Uniform and Beautiful End Pellet

- Easy Operation and More Stable

Main Technical Parameters

| Model | Dia .mm | RPM | L/D | Motor kw | Output Capacity kg/hr |

| KTE65 | 62.4 | 600/800 | 32-60 | 90/110 | 200-300 |

| KTE75 | 71 | 600/800 | 32-60 | 132/160 | 400-500 |

| KTE95 | 93 | 600 | 32-60 | 250/315 | 800-1500 |

| KTE135 | 135 | 600 | 32-60 | 500/900 | 1000-2000 |

There are 6 different cutting types for different application

According to your raw materials, We can customize the best solution for your business.

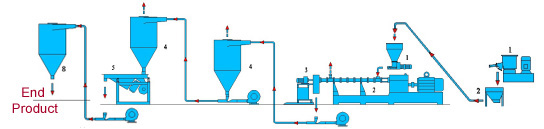

Water-cooling Strands Cutting Type

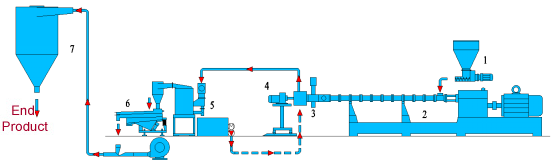

Air-cooling Hot-face cutting type

Water-ring Hot-face cutting type

Air-cooling strands cutting type

Water-flowing Cutting Type

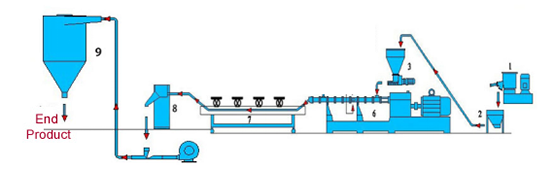

UnderWater Cutting Type

Wons Customers By superior Quality

- KERKE has over 11 years experience in compounding extruder;

- We produce core parts like screw elements, barrels by ourself;

- Our team are professional to ensure quality and service;

- Our extruders have been sold more than 60 countries.

Our Extruder Is Enough For You

- You should know that, Europe extruder quality is better than China, because of the steel level. If you can pay 5 times price, you can buy Europe brand;

- If your application is normal filler masterbatch, color masterbatch, engineering plastics, PET f lakes recycling etc. China extruder is enough for you. Will be no any problem;

- Kerke just provides high cost-effective extruder to you, not the highest, neither the lowest, but the more suitable for your business.

We Supply Good Extruder With Reasonable Price

- Extruder Price determines your end product production costper ton, Good price, better competitive advantage;

- Kerke extruder price can make you earn back equipmentinvestment in 2-3 months;

- We do not sell the cheapest extruder, just good qualityextruder at good price;

- You should care about the cheap extruder supplier, there areonly 2 reasons: 1. their quality is so bad with that so cheapprice; 2. That supplier does not have profit at so cheap price, can you imagine a supplier sell extruder with no profit? Howcan they promise the quality and service? I believe ourcustomers are smart, can not be cheated.

Service - Back Support For Your Business

- When you bought good extruder at good price, after-sale servicemeans more for your business success;

- Kerke can provide 7x24 hours a week after-sale service, wepromise you get our support in 2 hours;

- We can post you the spare parts you need in 24 hours;

- Kerke support team located more than 5 countries, China, Iran, Turkey, Indonesia, Pakistan, Mexico etc;

- Kerke service even including market analysis, project feasibilityanalysis, formula guide, competitor investigation etc;

- Your business success need a good partner - Kerke.